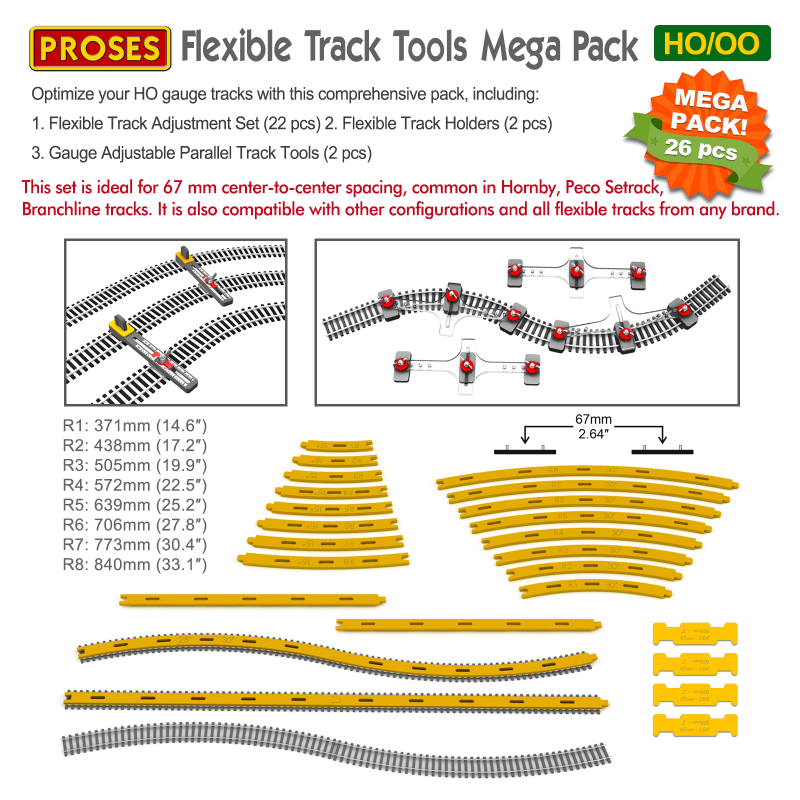

This set is made for curved track geometries featuring a track spacing of 67 mm (centre-to-centre). This track spacing is commonly used in Hornby, Lima, Jouef, Rivarossi, Setrack, and Branchline track systems, and can be used with all flexible tracks from any brand as well.

- 16 Curve Adjustment Pieces: 16 pcs set for flexible HO/OO tracks from 371 to 840 mm (14.6” to 33.1”) radius and includes settings for both 15° and 30° angles.

- R1: 371mm (14.6″) - R2: 438mm (17.2″) - R3: 505mm (19.9″) - R4: 572mm (22.5″) R5: 639mm (25.2″) - R6: 706mm (27.8″) - R7: 773mm (30.4″) - R8: 840mm (33.1″)

- Angle Specific Pieces: Within the curve adjustment pieces, 8 are tailored for 15-degree tracks and 8 for 30-degree tracks, providing versatility and precision for various track configurations.

- 2 Straightening Pieces: To complement the curve adjustments, the set includes 2 additional pieces dedicated to straightening flexible tracks, ensuring smooth and accurate straight sections.

- Ease of Use: This set is extremely useful when laying flexible tracks, making the process more efficient and less prone to errors. It's an essential tool for achieving professional-quality track layouts with minimal hassle.

Instructions for Use:

-

Select the Appropriate Curve Segments:

- Choose the curve segments based on your desired radius and angle. This set includes segments for curves ranging from 371 to 840 mm (14.6” to 33.1”) radius, with specific pieces for 15° and 30° angles.

-

Place the Curve Segments:

- Position the selected curve segments on the flexible track between the rails at the desired location. Ensure that the segments are properly aligned to achieve the intended curve radius and angle.

-

Fix the Tracks:

- Secure the tracks by nailing them to your layout. Use track nails to fasten the rails through the pre-drilled holes in the ties.

- Alternatively, you can glue the tracks to your layout if nailing is not suitable. Apply a small amount of Elmer's glue (white carpenters' glue) to the bottom of the ties and press the track firmly onto the layout surface. For helices, where nailing may not be possible, gluing may be preferred to ensure a stable and seamless curve.

-

Adjust and Verify:

- After fixing the tracks, adjust the curve segments to ensure they are correctly positioned and the track is smooth. Make any necessary adjustments to achieve a seamless connection.

-

Finalize:

- Once the tracks are fixed and adjusted, let the glue dry completely (if using adhesive). Verify that the tracks are securely in place and the curves are accurately set.

By following these steps, you can efficiently and accurately lay flexible tracks using the curve adjustment pieces, ensuring a smooth and precise track layout for your model railway.